MINING

Reactive Power and Large Filtering Solutions for the Global Mining Industry

NEPSI’s medium-voltage, metal-enclosed Products Meet the Challenges of the Mining Industry.

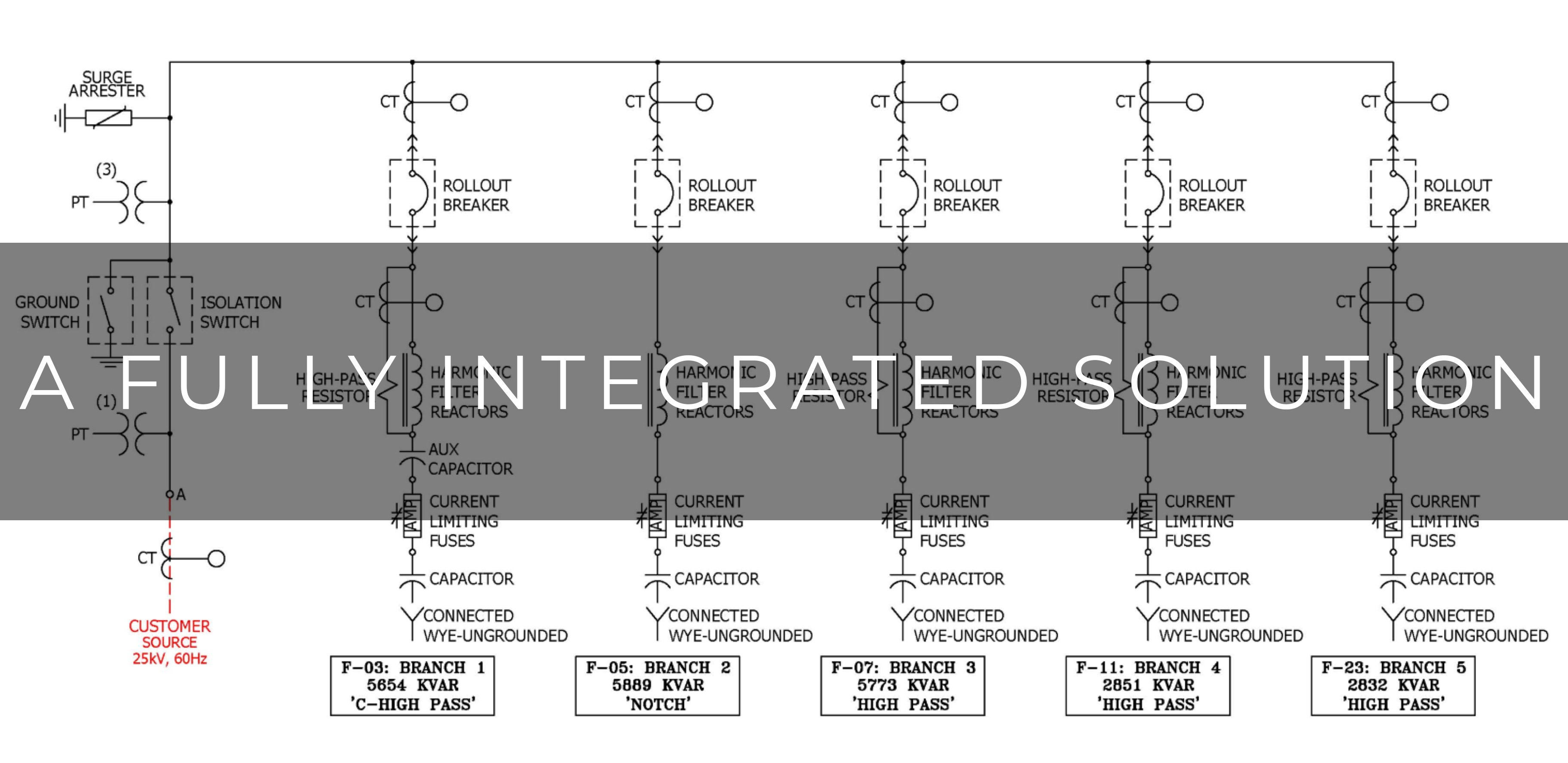

Mining and metal processing plants focused on mineral ore concentration, electrowinning, and smelting require large reactive compensation and harmonic filtering systems to mitigate poor power factor and harmonics associated with large complex drive systems, power converters, and rectifier systems.

NEPSI’s harmonic filter systems have become industry standard where the mining environment presents unique challenges, where reliability, safety, and ease of operation and maintenance are of upmost importance. NEPSI harmonic filter systems, when compared to alternate technologies (open-air erector sets), offers lower risks to the EPC, a smaller footprint where space is often critical, and ease of engineering and procurement by way of NEPSI’s specialized competencies and experience.

Don’t pay a higher price for your harmonic filter system; break it out of the GMD package. Come to NEPSI for project development, including: preliminary filter design and footprint drawings, budgetary quotes, and guide form specifications and specification development.

- Rodrigo Dünner,

International Sales and Marketing Manager

Advanced Filter Solutions to Meet Your Grid Code Requirements

Complex System, Simple Solution

Amongst other harmonic producing loads in the processing plant and mine, SAG mills, BALL mills, and conveyors that utilize cycloconverters and other solid-state converter technologies stress the power system due to their low power factor and varying characteristic and non-characteristic speed dependent harmonic content. Meeting grid code requirements is a noteworthy challenge requiring reliable complex multi-tuned harmonic filter systems. Often due to the size of the mine load, or the remoteness of the mine, the mine operation depends on the availability and reliability of the harmonic filter system; A filter system outage can lead to a plant shutdown. With over 20 years in designing harmonic filter systems and a proven track record for mine processing plants, you can rely on NEPSI.

Because of their advantages, metal-enclosed harmonic filter banks are now the preferred solution in the mining industry, being specified and recommended by most EPC’s and EPCM’s and validated by our end users.

- Staff Engineer - Major EPC

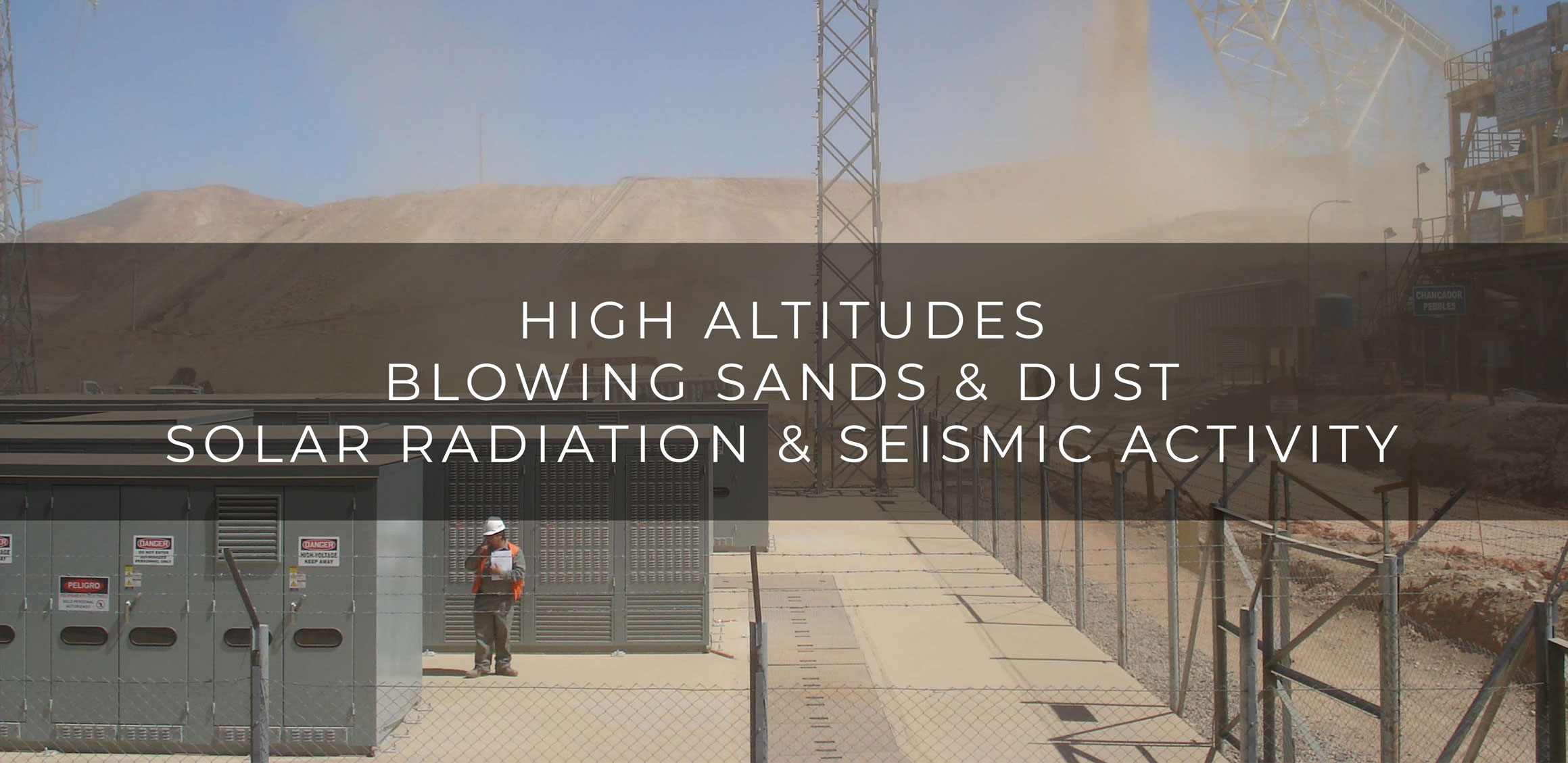

High Altitude Designs

De-rate Your Equipment and Don’t Forget to De-rate Your Labor

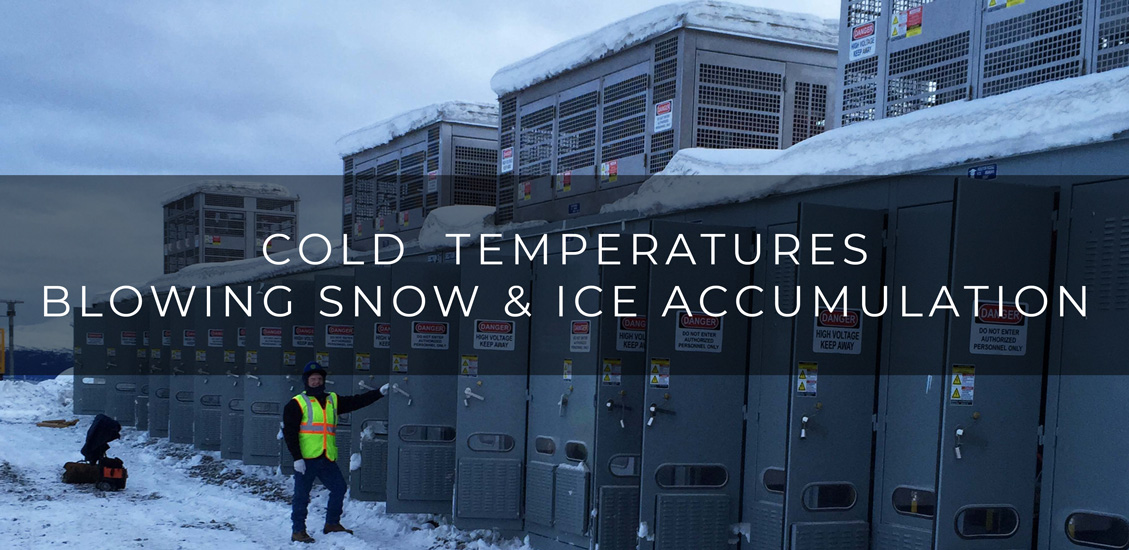

Unfortunately, valuable resources including copper, gold, silver, iron ore, and many more are located in mountainous regions, often reaching altitudes over 4,000 meters. Supplying filters into a mine is already a challenge, but installing at high elevation, where the air is thin, adds another level of complexity, one that NEPSI has done, and done again, and again.

NEPSI’s products are de-rated for altitude and are the best choice when compared to other technologies, including open-air erector sets. Our products come with all switching, all protection, and all control. They arrive onsite completely assembled, tested, and ready for interconnection, minimizing site labor and labor costs (room, board, travel, living quarters) where you can only expect 60% output from your work force.

When de-rating your electrical equipment, don’t forget to de-rate your site labor (studies have shown labor output to drop off by near 40% at high altitude). By doing so, you will see the true value in NEPSI’s solution.

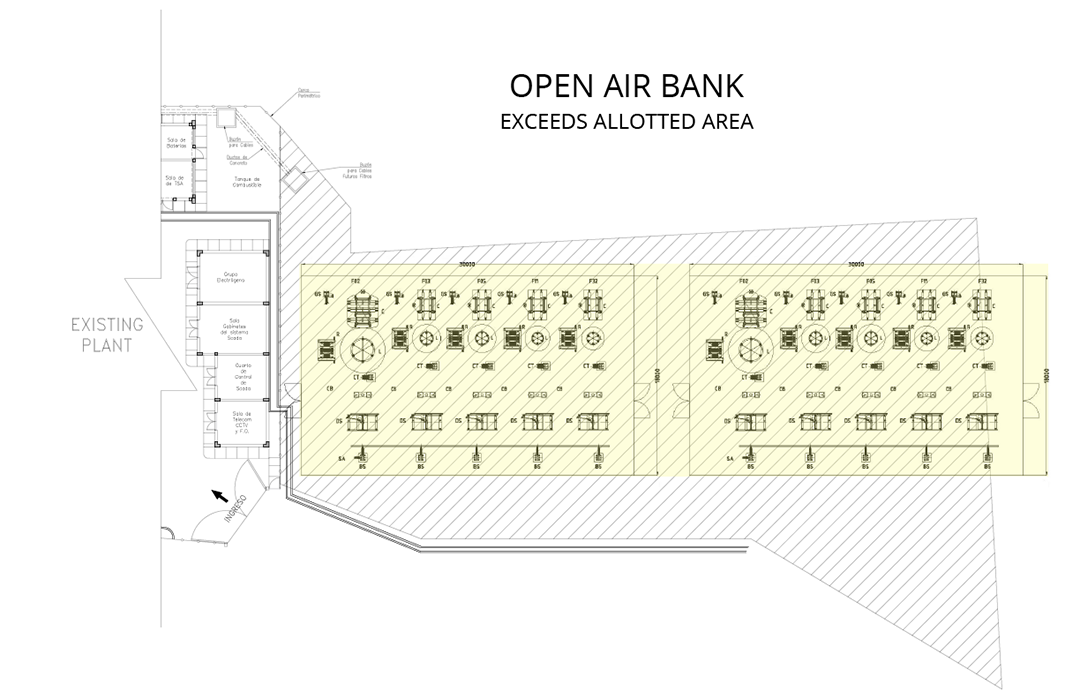

Space is Always at a Premium

When it comes to harmonic filters, footprint impacts substation costs, and the smaller the better. Often thought of as plentiful in the mine environment, it’s not. With altitude, comes bedrock, hilly terrain, and a shortage of area for your substation. With the high cost of excavation, which sometimes includes blasting, a smaller footprint can recover significant costs on your project. NEPSI’s harmonic filter systems have footprints that are 20% to 30% of the open-air erector-set alternative. If you’re looking to minimize site work, risks, and uncertainty that accompanies excavation, specify metal-enclosed harmonic filter banks from NEPSI.

See the difference for yourself! Simply hover over the image below for a real-world example of reducing your substation footprint.

Harmonic Studies, Harmonic Filter Design, and Study Validation

Detailed harmonic studies are most often performed by the GMD suppliers and consider many different plant operating scenarios, and supply contingencies. Filter design parameters are a key output of these studies. The study output, by no means is an equipment specification. NEPSI specializes in the development of filter systems from these studies and has been doing so for over 20 years. Not only do we develop a completely integrated harmonic filter package from these studies, we also validate the study by performing our own simulations with our industry recognized tools. In this way, you get a second set of eyes on the filter design and you can rest assured that the specified filter will meet your performance objectives.

Typical Product Mix

| Voltage Rating: | 24kV to 38kV | |

| Withstand Voltage: | Up to 200 kV BIL, 100 kV 1-Min., factory testing of complete assemblies | |

| Reactive Power Rating: | Scalable, 2 MVAR to 225 MVAR | |

| Number of Stages: | 1 Stage to 8 Stages | |

| Stage Ratings: | 2 MVAR to 20 MVAR | |

| Control: | Local | Remote, Automatic, and by Plant DCS System | |

Applicable Solutions

Metal-Enclosed Power Capacitor Banks | Web Page

Metal-Enclosed Power Capacitor Banks | PDF File

Metal-Enclosed Harmonic Filter Banks | Web Page

Metal-Enclosed Harmonic Filter Banks | PDF File

RC Snubbers | Web Page

RC Snubbers | PDF File

Applicable Specifications

Harmonic Filter Banks (No Feeder Bus) - Mining Spec. | MS Word

Harmonic Filter Banks (No Feeder Bus) - Mining Spec. | PDF File

Harmonic Filter Banks (With Feeder Bus) - Mining Spec. | MS Word

Harmonic Filter Banks (With Feeder Bus) - Mining Spec. | PDF File

RC Snubber - Guide Form Spec. | MS Word

RC Snubber - Guide Form Spec. | PDF File

Resources of Interest

The Metal-Enclosed Advantage | PDF File

Power capacitor banks and harmonic filter banks can be specified and purchased in two different configurations: “Open-Rack” or “Metal-Enclosed”. This technical note presents background information on these configuration options and provides compelling reasons why the metal-enclosed configuration is a better choice.

An Alternative To Neutral Unbalance Protection | PDF File

This technical note presents an alternate blown fuse detection scheme that utilizes direct fuse sensing. It cost less and provides better protection when compared to neutral-voltage and neutral current unbalance protection.

Harmonic Filter Design | MS Excel

Spreadsheet tool for calculating harmonic filter parameters. Filter types include: C-High-Pass (damped), Standard High-Pass, and Notch Tuned (Delta and Wye Connected) filters.

Extra Content Around the Web

Videos

The Simplicity of Installing Metal-Enclosed Harmonic Filter Systems

Harmonic Filter System Designed for Copper Concentrator Plants

Arc Flash Hazard Mitigation (Embracing 0-HARM)

Deep Dive Into Real World Harmonic Filters - Large 75 MVAR 5-Stage Filter System Destined for a Large Copper Concentrate Plant

Technical Notes

Altitude Derating of Metal Enclosed Harmonic Filter Banks

Arc Flash Hazard Mitigation in Metal-Enclosed Power Capacitor Banks and Harmonic Filter Banks

MTBF (Mean Time Between Failures) and MTTR (Mean Time to Repair) for NEPSI’s Metal-Enclosed Solutions

LinkedIn Posts

Capacitor Banks and Harmonic Filter Banks for Underground Mining Applications – Yes we are underground too!

Factory Acceptance Tests (FAT) Successfully Completed on Metal-Enclosed Harmonic Filter System Destined for Large Copper Concentrate Plant

NEPSI Continues to Grow In South America and Hires Rodrigo Dünner to Support Latin America Mining Industry

NEPSI Breaks World Record! Heaviest Single-Stage Metal-Enclosed Harmonic Filter System Ever Shipped

You’ve seen the heaviest...now see the longest. Meet Bigfoot!

HUGE Iron-core Filter Reactor! Large Single Stage C-HP Filter

How many medium-voltage metal-enclosed reactive power solutions have we sold and where did they go?

Calculators

Altitude Correction for High Elevation Projects – The Right Way to Do It per IEC and IEEE Standards

References

Partial Mining Experience for Large Harmonic Filter Systems

Follow us on social media for up-to-date news, videos, and other information: